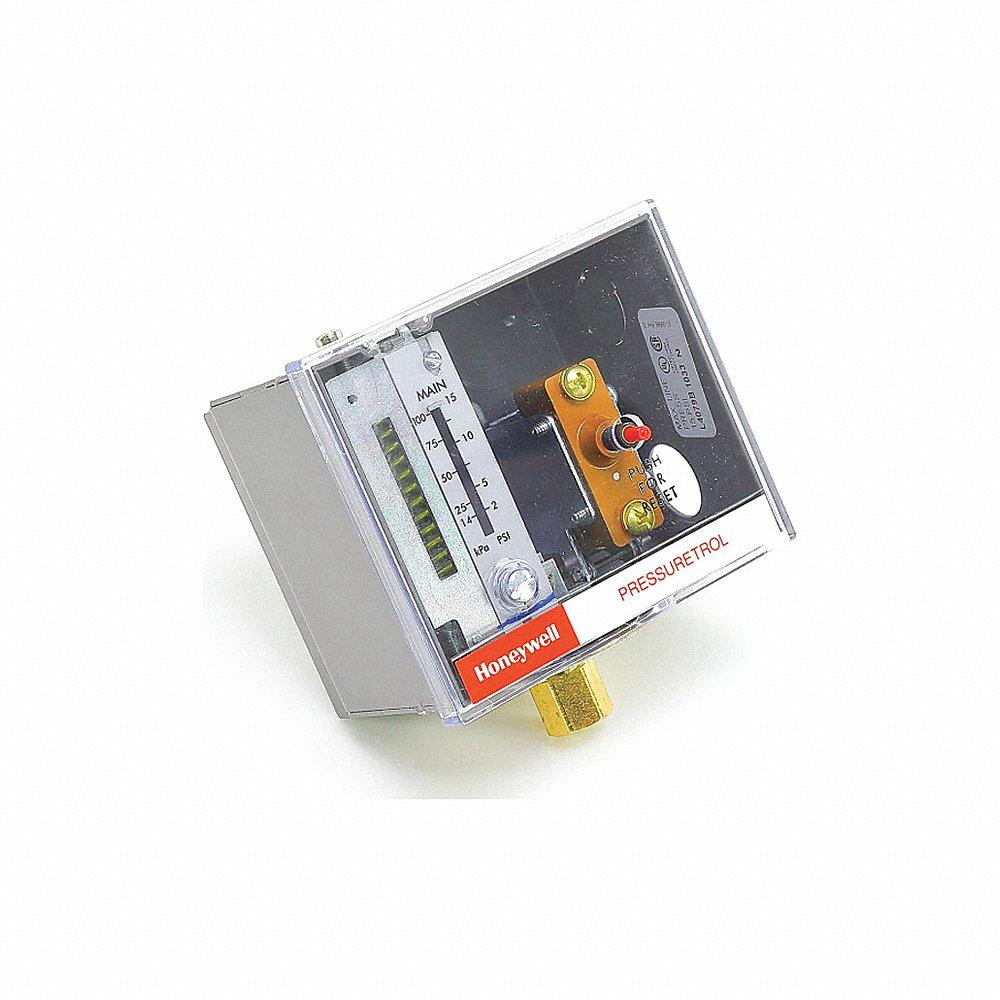

HONEYWELL 壓力和真空開關 設計用於在壓力超過指定設定點時快速打開/關閉迴路。 具有耐用的玻璃纖維增強聚酯外殼和感應壓力變化的隔膜致動器。 提供標準和反向動作變體。

設計用於在壓力超過指定設定點時快速打開/關閉迴路。 具有耐用的玻璃纖維增強聚酯外殼和感應壓力變化的隔膜致動器。 提供標準和反向動作變體。

HONEYWELL -

壓力開關

| 次數 | 型號 | 價錢 | |

|---|---|---|---|

| A | L4079B1033 | NT$11,560 | |

| B | C6097A3004 | NT$9,746 | |

| C | 76055-00001000-01 | NT$5,340 | |

| D | C6097A3012 | NT$10,742 |

HONEYWELL -

壓力開關

霍尼韋爾壓力開關用於提供電氣反饋,以響應腔室上升或下降至預定壓力水平。 這些裝置採用玻璃增強聚酯外殼,帶有能夠現場調節的螺釘端子連接和兼容多種流體的 Kapton 隔膜。 它們進一步設計用於與不同的端子(Metri-Pack 連接器)配合使用,連接時形成緊密密封。 從這些壓力開關中進行選擇,提供 750 PSI 和 1250 psi 爆破壓力型號 Raptor Supplies.

霍尼韋爾壓力開關用於提供電氣反饋,以響應腔室上升或下降至預定壓力水平。 這些裝置採用玻璃增強聚酯外殼,帶有能夠現場調節的螺釘端子連接和兼容多種流體的 Kapton 隔膜。 它們進一步設計用於與不同的端子(Metri-Pack 連接器)配合使用,連接時形成緊密密封。 從這些壓力開關中進行選擇,提供 750 PSI 和 1250 psi 爆破壓力型號 Raptor Supplies.

| 次數 | 型號 | 行動 | 爆破壓力 | 歡迎留下您的聯絡資訊 | 工廠開/關設置 | NEMA號 | 範圍 | 價錢 | |

|---|---|---|---|---|---|---|---|---|---|

| A | 76575-B00000040-01 | NT$4,061 | |||||||

| A | 76052-B00000150-01 | NT$4,020 | |||||||

| B | 76054-B00000600-01 | NT$4,132 | |||||||

| A | 76051-B00000020-01 | NT$3,755 | |||||||

| A | 76053-B00000300-01 | NT$4,089 | |||||||

| A | 76055-B00001000-01 | NT$4,153 | |||||||

| A | 76576-B00000100-01 | NT$3,830 | |||||||

| B | 76064-B00000600-01 | NT$5,106 | |||||||

| B | 76061-B00000020-01 | NT$4,414 | |||||||

| A | 76577-B00000040-01 | NT$4,489 | |||||||

| A | 76580-B00000100-01 | NT$4,637 | |||||||

| A | 76072-B00000150-01 | NT$5,327 | |||||||

| A | 76074-B00000600-01 | NT$4,823 |

功能

- Honeywell pressure switches feature a glass-reinforced polyester enclosure for durability and a diaphragm actuator to sense the pressure change.

- These units have a Kapton diaphragm compatible for use with a wide variety of fluids.

- They are further designed to work in conjunction with different terminations (Metri-Pack connector) which forms a tight seal when connected.

- They are available in 750 PSI and 1250 psi burst pressure variants.

工作機制

- Apply pressure or vacuum to the sensing element.

- Sensing element deforms in response to pressure or vacuum.

- This causes the movement of a diaphragm or piston and activates a switch mechanism.

- The switch mechanism then completes or interrupts an electrical circuit based on the pressure or vacuum level.

- Finally, the electrical circuit controls associated equipment or triggers alarms.

常问问题解答

How do I install Honeywell pressure and vacuum switches?

- Securely mount the switch using appropriate fasteners, ensuring it is positioned correctly.

- Connect the electrical wiring to the terminals of the pressure or vacuum switch according to the wiring diagram provided.

- Test the operation of the switch to ensure it functions correctly and responds appropriately to changes in pressure or vacuum.

- If required, adjust the switch settings according to the application requirements.

- Once tested and adjusted, securely fasten any connections and ensure they are properly insulated.

- Conduct a final inspection to verify that the switch is installed correctly and is ready for use.

What factors should I consider while choosing a pressure and vacuum switch?

- Select a switch with the necessary accuracy to meet your operational requirements.

- Determine if the switch allows for easy adjustment of setpoints to accommodate varying pressure or vacuum levels.

- Consider the response time of the switch to ensure it reacts quickly to pressure or vacuum changes as needed.

- Assess the operating environment for factors such as temperature, humidity, and exposure to corrosive or hazardous substances, and choose a switch that can withstand these conditions.

- Ensure the switch's electrical rating matches your system requirements to prevent overload or failure.

- Choose a switch with mounting options suitable for your application, whether it's panel mount, pipe mount or other configurations.

- Select a switch from a reputable manufacturer known for producing reliable and durable products to minimise the risk of failure.

- Check if the switch meets industry standards and certifications relevant to your application, such as UL, CE or CS

What safety precautions should I take while using a pressure and vacuum switch?

- Operate the switch within specified temperature, humidity and environmental conditions outlined in the manual to prevent damage or malfunction.

- Follow electrical safety procedures when connecting the switch to power sources, such as turning off the power before installation, using insulated tools and wearing appropriate personal protective equipment.

- Do not exceed the maximum pressure or vacuum rating of the switch to prevent damage or failure.

- Periodically inspect the switch for signs of damage, wear or corrosion and replace any worn or damaged components promptly.

- Establish procedures for emergency shutdown in case of switch malfunction or unexpected pressure / vacuum conditions.